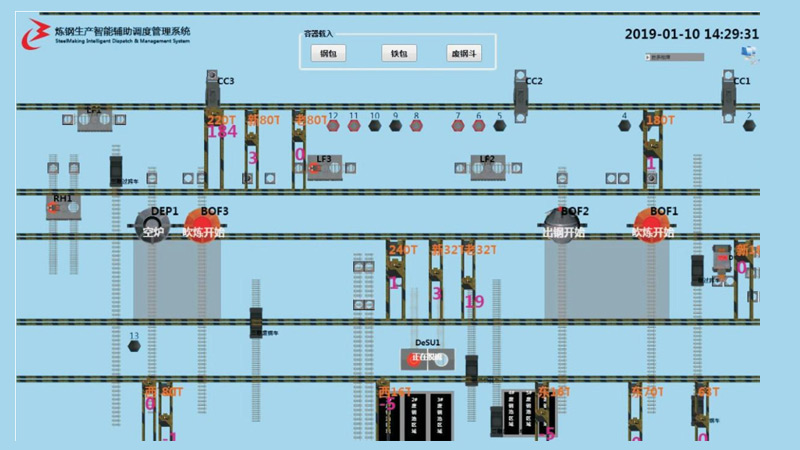

Steel-making logistics tracking and intelligent scheduling management system aims at establishing steel-making big data platform, enhancing data collection and analysis of production layer and management layer, expanding application of improved technology, focusing on material flow and weight data, collection an analysis of machine status data, meanwhile, it automatically tracks molten iron, molten steel...

Contact

Overhead crane positioning and status tracking

Ladle car positioning and status tracking

Scrap bucket identification and tracking

Steel making big data platform: logistics data management, energy data management, machine status data management, technological parameter data management, etc.

Iron ladle identification and tracking

Steel ladle identification and tracking

Slab/billet identification and tracking

Steel management: baking management, ladle life management, on/off line management

Intelligent scheduling: overhead crane intelligent scheduling, ladle car intelligent scheduling, container intelligent scheduling

Using coded cable wireless sensing technology to realize real-time position detection of cranes and bogies, continuous absolute position detection with an accuracy of 2mm to meet the requirements of unmanned crane positioning

Intelligent hardware, self-test equipment, easy to maintain; abundant interface; high temperature resistance, dusty and other harsh industrial environments resistance, long life.

The earliest research on intelligent scheduling algorithms for the steel industry, with a professional algorithm research team composed of doctors and masters, with rich project implementation experience.

Invention patents with independent intellectual property rights.

Steel-making logistics tracking and intelligent scheduling management system consists of: scrap management, molten steel pre-treatment management, converter production management, refining production management, continuous casting production management, steel ladle management and warehouse management subsystem.

Steel-making logistics tracking and intelligent scheduling management system consists of: scrap management, molten steel pre-treatment management, converter production management, refining production management, continuous casting production management, steel ladle management and warehouse management subsystem.

copyright Hunan Qianmeng Industrial Intelligent System address:28 Kangwang Industrial Park, Yueyang record number:湘ICP備20000218號(hào)-1business license

Technical Support:Competition network