Taking “balanced the gas transmission” as the core, the intelligent pressure control system for gas collecting process integrates feedforward mechanism analysis, intelligent feedback control, expert coordination control, big data rule mining and model online optimization . According to the volume and distribution of raw gas transmission, the evaluation indexes such as the coal-loading smoke dust control rate , the stabilization of carbonization chamber pressure micro-positive pressure and gas collecting tube pressure are taken to build mechanism model of pressure system for gas collecting process which combined fluid mechanics analysis with intelligent control algorithm in the analysis of its fluid mechanism of raw gas transmission.

contact

System controls the pressure of single carbonization chamber

which ensures constant micro-positive pressure for carbonization chamber pressure in the whole coking process.

System realizes auto-uncap for lifting tube cap

which brings higher stability for operation and lower labor intensity of workers

System analyzes the transmission

of raw gas with fluid theory, and builds mechanism model for the system of gas collecting process control

Coordination control between the high pressure of ammonia

water and the pressure of gas collecting process, which Reduced the impact of high-pressured ammonia water on gas gathering process and avoided secondary smoking caused by coal-loading dust returning to the chamber.

Coordination control with multiple objects

the liquid seal device of carbonization chamber, the water seal cap of lifting tube, the pressure control valve of gas collecting tube, great circle valve and air blower, which ensure stable pressure in gas collecting process.

System corrects model online

with data center, so as to adapt to different environments.

Obtain coordination rule by mining

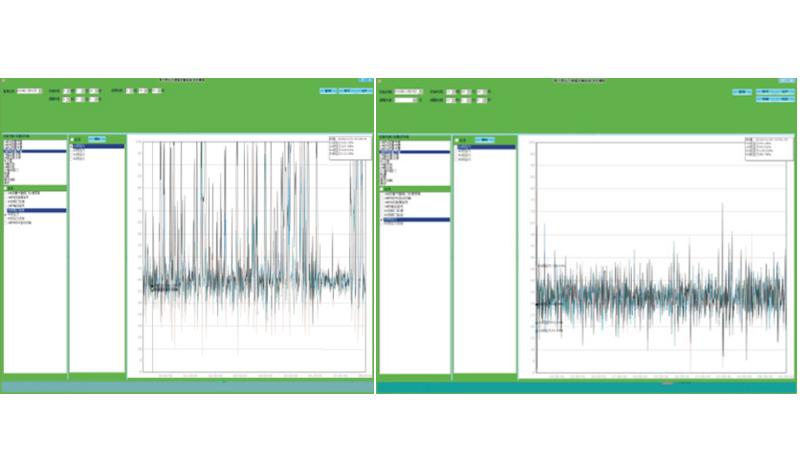

algorithm intelligently, which better supports the process of intelligent coordination control and coking production.Before and After: pressure curve of gas collecting tube

The hardware of system, which is easy to extend and low maintenance costs, is structurally flexible and able to configure according to the site. Both data collecting and system running are stable and credible, and the whole debugging process will not affect normal production.

copyright Hunan Qianmeng Industrial Intelligent System address:28 Kangwang Industrial Park, Yueyang record number:湘ICP備20000218號(hào)-1business license

Technical Support:Competition network